How to Plan Production Around Chinese New Year

Learn about:

- Planning your production for the Lunar New Year

- Meeting your customers’ demand

- Demand and supply planning

During the Chinese New Year, production can be problematic for many business owners and vendors within the supply chain. Items that are routinely available will likely have a delay during the holiday. The Lunar New Year typically has workers out of the factories for a minimum of one month. Therefore, it is necessary to plan ahead to have the appropriate supplies needed from Chinese and other East Asian factories.

Without proper planning and implementation of appropriate safety stock, there is no guarantee that a supplier will have the necessary materials to operate and send to customers during this extended time. With that possibility, some strategies worldwide are essential to put into practice to help businesses, retailers, and vendors account for proper supply chain acquisition to ensure an appropriate amount of materials throughout the year, even with disruptions.

How do I forecast my production around closures due to the Lunar New Year?

There are two primary ways to plan for appropriate safety stock during Lunar New Year production times that are both effective and common. Both options allow vendors and suppliers to analyze their present and future output and make proper plans to accommodate the amounts needed during the holiday.

Demand planning

When suppliers use demand planning to account for production during the Chinese New Year, they look at the historical sales data they have compiled from previous months and years of business. It is essential to take the time to look at trends in supply orders and compare them with current demand.

After this step, vendors should consider the sales forecasts they have for the coming months and take the opportunity to compare them with growing or decreasing demand in the industry. This comparison allows suppliers to identify product demand by observing increased marketing initiatives for items that include particular supplies or by monitoring news outlets for reviews and studies of certain materials and products, among other things.

A demand plan helps suppliers more reliably establish how much inventory they need to keep up with the demand they need to meet.

Supply planning

The next step to plan for closures is to create a supply plan. When identifying needs for production during Chinese New Year, suppliers need to take the information obtained during demand planning and develop actionable steps to acquire the required items for future orders.

Vendors have to plan for a pause in routine deliveries during the Lunar New Year production times. If a supplier runs out of the necessary materials for its orders, that supplier will find it challenging to obtain them promptly during the observance.

How do I continue to meet demand?

Suppliers must incorporate strategies within their organization that address the gap in supply acquisition. This act will allow suppliers to continue meeting the need of their customers. For newer companies, it is harder to gauge adequate levels of stock due to limited historical data. However, businesses that have been around for a longer time can refer to trends and sales to more accurately prepare for the Lunar New Year.

Suppose a supplier does not have adequate information to make a solid plan. In that case, it is vital to create a six-week minimum safety stock of the average supply and material amount used in the months of operation that a vendor has had.

It is vital to note that many retailers will place large orders with vendor factories right before the holiday, causing a massive uptick in the amount of work the factory has to complete before the month-long holiday begins. Due to the larger than average amount of work and the compressed timeline, quality control can start to slip. Therefore, it is in suppliers’ best interest to place their orders for additional materials well before the shutdown occurs.

Suppliers should place their orders a minimum of three months before the holiday. Placing orders earlier will allow for a higher quality product or material and peace of mind in that the supply will be at the needed level.

Vendors must be mindful in researching any potential shortages in raw materials that may contribute to an issue within the supply chain. If the materials are not available, the rest of the supplies will be unavailable as well. Holes in the supply chain will cause even longer delays in acquiring the necessities for products.

One way to avoid a potential bind is to establish a relationship with a regional emergency vendor to work with on a dual basis with the international supplier. Although this source will not be the primary vendor, suppliers can use it if they run into a supply shortage and need additional resources.

Lunar New Year production insights

Although there is difficulty associated with a lapse in production, there are strategies to alleviate the situation’s stress. When suppliers take the steps to accurately define the necessary stock levels that they need to operate efficiently, it reduces the amount of pressure on the organization.

The Chinese New Year is a big holiday to plan for in terms of supply. However, there are other issues and events that an organization can encounter as well. These can include weather issues, political unrest, staffing shortages, and even health disasters. The COVID-19 pandemic has brought such problems to light just recently. With this in mind, it is critical to plan for Chinese New Year production and other extenuating circumstances that can arise.

With a set plan to manage supply and demand, you will have peace of mind fulfilling orders that come your way. Not only will your inventory be stable, but orders will continue processing as usual.

Use machine learning to plan your supply chain

With SupplyPike’s Retail Intelligence app, you can leverage the power of machine learning to plan your supply chain around production closures and other hiccups. Prepare for the Lunar New Year with actionable insights.

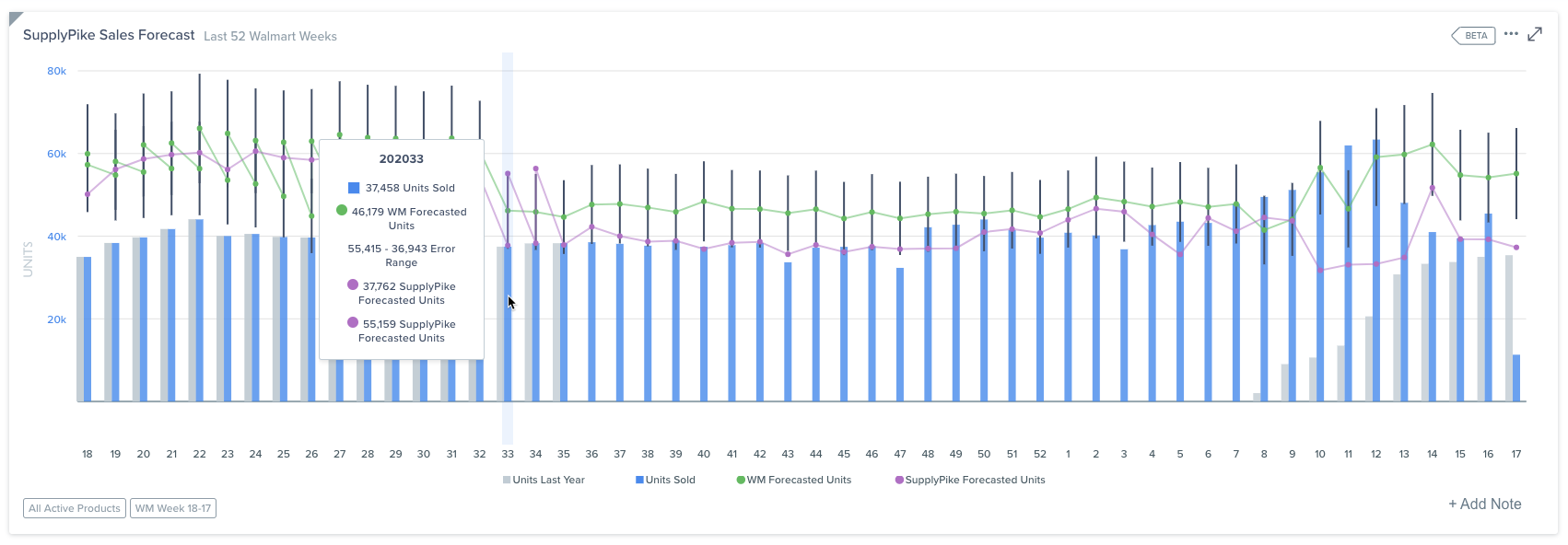

Use the SupplyPike Sales Forecast tool to configure a demand plan and get ready for holiday closures.

Retail Intelligence – SupplyPike Sales Forecast Tool

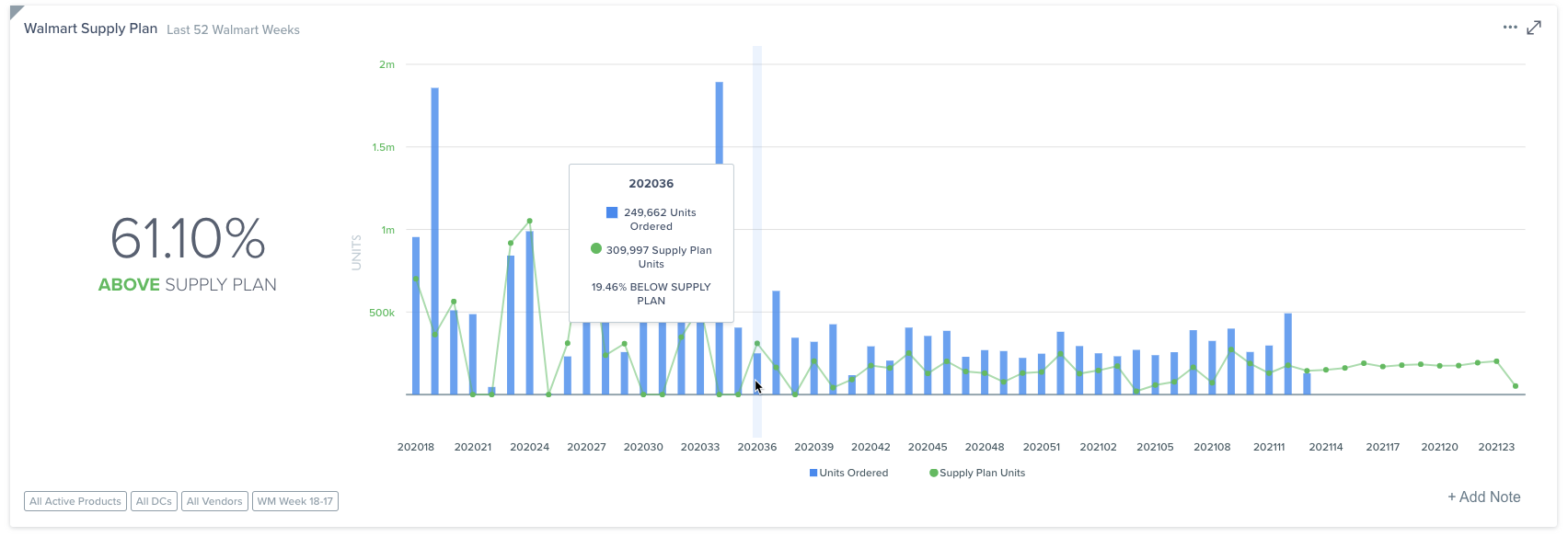

Use the Retail Intelligence Supply Plan dashboard to view your weeks of supply and update your sources.

Retail Intelligence – Walmart Supply Plan

See your data in action for free today!

Related Resources

Written by The SupplyPike Team

About The SupplyPike Team

SupplyPike builds software to help retail suppliers fight deductions, meet compliance standards, and dig down to root cause issues in their supply chain.

Read More

About

SupplyPike helps you fight deductions, increase in-stocks, and meet OTIF goals in the built-for-you platform, powered by machine learning.

View SupplyPike's Website