Walmart Shipping 101

Transcript

[00:00:00] Danielle: Welcome everybody. We hope you're all having a wonderful day so far. We have a lot of good content that we are going to get into today with Walmart Shipping 101. So before we start, we always like to introduce ourselves. My name is Danielle Gloy. I will be monitoring the chat today and then leading our content is the incredible Allie Truong.

So we work on the SupplierWiki team. SupplierWiki is like the educational arm of SupplyPike, So we help create free educational resources like ebooks, articles, and webinars. Our goal is to make content that is going to be the most beneficial to you and that is ultimately going to set you up for success.

So if there is specific content that you maybe want to see more of, or even if there are some topics that you would like us to explore, please feel free to reach out to us. We would love to help you. And so moving on to the agenda for today, we have a packed one for this hour. we're going to start off covering some packaging basics.

So just going over different pack sizes and palette types, and mainly covering key terminology essential, for shipping. And then next we'll dive into truckload types and parcel shipping basics. So we'll discuss how to choose the best shipping mode, taking into consideration things like delivery speed and product type, and then moving on.

We'll explore choosing collect versus prepaid, and this is where we'll discuss the pros and cons of each option. And then we'll begin wrapping up the content portion by going over essential shipping documents and how to maintain compliance with shipping regulations. And finally, we'll open the floor, to general questions and discussions.

Please feel free to ask any questions you have about today's topics, or maybe even share some challenges that you've encountered, in your packaging and shipping processes. We love some engagements in the chat. So a few FAQs that we typically get during webinar. The first one is, will we be getting a copy of the slide deck?

Yes, absolutely. so you can expect to see this PDF version, as well as the recording of this webinar, appear in your email inbox in about 10 You can also find our webinar recordings on YouTube under SupplyPike, or you can find them on our SupplierWiki website where you can download a variety of our slide decks.

It's not just limited to this webinar. And secondly, what is the best way to ask a question? So at the bottom of your screen, you'll see a Q& A tab that has two little text bubbles. And this is where we ask you to please submit any questions related to the content as I will be able to monitor them and then see them up for Allie for the Q& A time at the end.

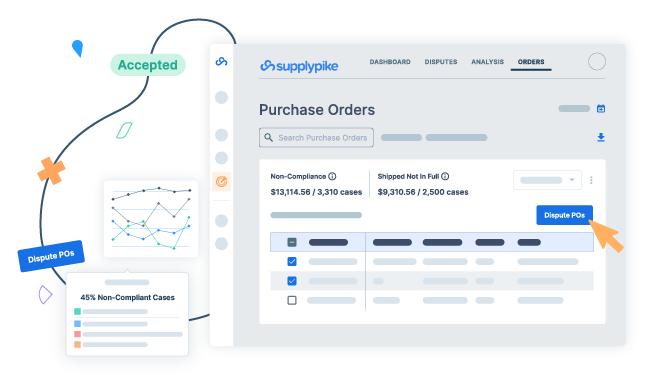

And if you have any questions about the content, send them in early. I may interject sometime during the webinar if there is maybe a question pertinent to the content that Allie is going through, but for the most part, I will be saving those questions for the end. So last thing before we get into the content is If you are new to our webinars or have never heard of SupplyPike, SupplyPike is a platform that enables suppliers to get paid and get better.

we do this with a software that identifies, recovers, and prevents deductions and compliance issues. And we also do this with a lot of different retailers. Some things we specifically cover at Walmart include like AP deductions, OTIF, SQEP, overages, et cetera. So anything that could be impacting your bottom line.

We have built these tools to help target and resolve those revenue loss issues. And just a little shout out, we work with a lot of great suppliers. We have some of them up here today. And if you aren't currently working with us, we would love to see your brand's logo up here in the future. But in the meantime, I'm going to hand it over to Allie to get into today's content.

[00:03:59] Allie: Awesome. Thank you, Danielle. Appreciate it. And we're going to get, go ahead and get into today's content. I will say the allergies this season have really gotten me. So if I mute myself during this or my voice starts to go out, please just bear with me. but hopefully it's not affecting you or your families as well.

Cause this year is really just. Anyways, we're going to talk about packaging basics and we're going to start with pack sizes. So this can be a point of confusion for new suppliers specifically because there's a lot of lingo in the industry and it depends on the retailer how they refer to these. So we're going to define what these particular names mean for the different pack sizes and when they'd be used.

So if you hear someone say VendorPack, that's going to be the outer box, and it should have an easy to scan label. And that label should not be, and we'll get into this later at the UPC level, but rather for that VendorPack. And then within that is a smaller grouping of which is, the WarehousePack, The reason that it's called the Warehouse Pack is because, let's say, they, Walmart receives the Vendor Pack, they'll open up that box, because they know that it's a Vendor Pack and it's labeled as such, and then they say, okay, each of these go to different warehouses, so I, we need to unpack this box, send them to different warehouses, and then within that is the SKU, and that's going to be the smallest version of the product, so If I'm a customer at Walmart, whatever I scan, that's gonna be the sku.

So that, one type of product, that one unit. and so we'll go into kind of what each of those mean. So for vendor pack, that's going to be referred to in a couple different ways. So if you hear vendor pack, you may also hear master pack, you may hear case pack, you may hear break pack. all of those can be interchangeable.

Particularly at Walmart. I won't speak to how other retailers necessarily. Speak to those. if you do have an interesting call out, you can share that in the chat. We'd love to hear it. But VendorPack means all of those things and that means that it's going to go from the suppliers, the supplier to the retailer's distribution center or fulfillment center.

And then Walmart specifically has minimum and maximum requirements in terms of the size. So making sure that you're adhering to those specifically. are extremely important because you will receive compliance fines and you will have a myriad of supply chain issues if you're not meeting these requirements.

And let's just say that we may have some examples on this. Let's just say, you're not shipping a full pallet's worth. Walmart in their secondary packaging guide does explain how they expect you to pack specific pallets and organize that for efficiency in the supply chain, whether that's how they're getting loaded into trucks.

How, what, is going to balance and be easy to transport on a pallet, etc. So we do have resources on the secondary packaging guide for Walmart. If you haven't read that, please go download it. Danielle can find the link for you guys really easily and send them in the chat. But we also have our cheat sheet that covers that and calls out some of those main things that we see suppliers asking about.

Alright, so we've gone from our, vendor pack to our warehouse pack. This can also be called an inner pack, which makes sense because it's that inner middle part of the vendor pack and it's always going to be inside of the master pack. So there, there are options to pack some. Some suppliers won't use a warehouse pack and they'll just have, their vendor packet and SKUs.

We'll talk about that. That's going to depend on your business, your specific category, etc. But essentially with the warehouse pack or the, or if it's, you're calling it the inner pack, it's going to contain one or more eaches. So that's how it's going to get broken out. And those can be, distr Distributed how they need.

An example would be, let's say you've sent the vendor pack and store 237 needs two warehouse packs and another store needs one, you can ship them out that way. So it's a really easy way to break up product and ship it while still keeping it contained and not damaging those smaller units such as a UPC or a SKU.

All right, and as I mentioned, there's a link to that in the description. and I'll see you in the next video. We went, we were talking about case packs and breakpacks. So yes, it's going to be a vendor pack, but it depends on what's inside. It's like what they say, it's the inside that counts when it comes to case packs or breakpacks.

So let's talk about what those are meaning, because it's a little bit extra information when it comes to that. So with a breakpack, you're going to have It makes sense. It's letting the user, whoever's interacting with that, know that it's going to be something that's going to be broken apart. So it's going to be taking that vendor pack and breaking it into those inner packs, or warehouse packs, whatever you like to call them, whereas a case pack is going to have those individual SKUs in it.

just to reiterate, A vendor pack is going to be greater than a warehouse pack, whereas a vendor pack, in the case pack sense, is equal to a warehouse pack. just helpful to understand and level set, especially when you're building out, your, labels that are identifying those and letting the, Processing or the Receival process.

Those, either automation or manual workers know how to treat your particular product. All right, and then palettes are a big deal. Actually, something that we are seeing a lot with the suppliers that we work with currently is that palettes have been, something that has been getting fined a little bit more, broken palettes are getting fined more in the SQEP program.

So that's really key to call out. We'll talk about that The compliance section of this and how that impacts suppliers and how those fines are allocated later. But I want to just call out here that we are seeing a rise in pallets being damaged. And so it's really important to consider how you as a supplier can be accountable for those issues and then in turn how you can start disputing any of those that are actually on the responsibility of either your 3PL or the retailer themselves.

first thing to consider is how your product needs to be packaged. Like I said, let's say you have really small, convenience items, such as, candy or something in the impulse section, like a smaller toy. You may, if you're sending, master packs and you're sending it on a pallet, you may want to have those inner packs so you can ship them to specific stores.

Whereas, it wouldn't make sense to put your SKUs into, a master pack or a vendor pack level without those inner packs, cause it's just really too much product that, a store probably want on hand at one time. Another thing to think about is how many of your products can fit on a palette. A lot of suppliers have seen efficiency in increasing that amount, being able to pack, smarter, whether that's down to the organization or the packaging design of the actual, each.

Or SKU, rather. So thinking about that, I mentioned this in my prior example, but how your pallet will be parceled out from warehouse, DC, store, to customer. So if you're in a slower moving category like electronics, you may want to, have, A smaller version that you're sending to the store, maybe you only need to send one or two, whereas like an impulse item, you're probably going to need to send more inventory at one time if they're, if it's something that's going through pretty regularly.

And then lastly is how Walmart's initiatives in packaging, tech, and manufacturing can affect your business. One example that I'll just mention off the top of my head is Walmart's movement at their DCs and their FCs to incorporate automation. That's huge. That's something that they've been talking about for years now and that they're making strides in for automating.

But if you're not packaging your, pallets correctly, your master packs, your labels are incorrect, it's going to create a hiccup in the process. And thus that. will create an issue for maybe on time and full, maybe having all the, correct, the correct inventory at the right time, right place. So making sure that you are understanding, keeping up to date with those, it's going to make you be a seller supplier rather than one that is causing issues and affecting the category or, the, store at large.

And then the last thing I'll say about palettes here is the Standard is 40 to 48. That's the US standard. In Walmart's Secondary Packaging Guide, because I have read it a couple times, all 200 something pages, there is a mention, I believe, of pallet companies that Walmart does prefer suppliers to use. So you can go find that and see if that's something that you'd like to change, especially if you have a pallet supplier that you've continuously had issues with.

It may be pertinent to change that small detail, but can really affect a lot of things. Alright.

Okay, let's talk a little bit about load quality and pallet standards. There are a few critical measurements to follow when shipping pallets with Walmart. And here are the minimum pallet standards. First is deck coverage, so the maximum spacing between each pallet. DockBoard is four inches. And then making sure that they're grade A, four way, flush, and non reversible. So if you are shopping for palettes, this is the standard here.

All right. I'm sure if you have been a supplier for a little bit, you are familiar with hi. And it's one of those jargon terms in the CPG space, in the retail space. that if you read it, it's not necessarily intuitive. So we want to break it down and make sure people understand what that means. So tie is going to be the number of boxes that one store, that one can store on a particular layer on a palette.

So that's, think about it, since we're all in spreadsheets all day, think about it as your, rows. So how many rows if I'm highlighting those or filling those rows, those are actually the number of boxes that I could put on a palette. if my product is something like a case of water bottles, maybe I can only stack four across the palette before it's, filling over the edges.

So that's something to think about. And then, high, that one kind of, is a little bit more intuitive to me, because I think of like, how high can it be stacked? So that's the number of layers, that the box can be stacked, or the columns rather, if we're thinking of our spreadsheet example. So when you put tie high together, it's how many can I stack on a row, and then how many columns can I make within that, and how high can those columns go?

And why is that important? It's important because you want to build a stable palette. We have all seen, some blooper reels, I'm sure, of palettes that have been just utterly destroyed, whether that's when they're getting picked up by the forklift or they're not shrink wrapped correctly. so here are just the basics when it comes to stacking a stable palette.

First, put the heavy goods on first. If you're doing a mixed palette, which can have its own issues, or it can be a really great solution. Just depending on how you, tackle it. You want to make sure that you're putting the heavy goods first. Pretty common sense, that's how we do our groceries.

You don't put, your jug of milk on top of your eggs, makes sense. Another thing is stack to the edge. So it's really important to stack to the edge, but not over it, because when you're stacking over it, essentially, if you're thinking about those slots that pallets are getting put in, it may not fit. And then, If someone's not paying attention to it being over, it may damage your goods.

It may damage someone else's goods. So make sure that you, if you're stacking to the edge, that is not even a centimeter over. The next part about building a stable palette is the brick pattern. That is the most stable way to lay products. That's actually outlined in the secondary packaging guide. They show a couple of different examples of how you can stack palettes.

So if you're seeing a lot of issues with. Damaged goods or, some of those SQEP finds. Let's think about, could the root cause be the way that we're stacking our pallets? And then lastly, another table stakes one is strapping product down before shrink wrap. a lot of suppliers will go ahead and put their pallets down, put their product on, and then shrink wrap it, but strapping them down can just reinforce that shrink wrap, because even if you wrap it really tight, Sometimes with the way things go, it can just, it can move around and then the shrink wrap isn't really doing much except holding its once perfect form.

All right, let's talk a little bit about strategic pack sizes. So there's a balance between shipping costs and replenishment cadence as with all supply chains. It's a balance of all the different variables that you have to deal with. So if you're think, Really start with thinking about what you're, you need for your product, your replenishment cycle for your specific category.

If you're shipping, some of those onesies, twosies, like you have your, standard product, but then you have some new innovation that may be the, thing that's causing you the most issues.

We're gonna make it through, guys. Allergies and all. okay. let's say a bigger pack size makes more sense for you. You want to ship more product to a Walmart DC for them to distribute across the network. What are some of the benefits? The packaging is going to cost less. You're shipping more on one pallet.

It makes sense. The other is more product can be shipped at once. And if you have a high turn rate for your product, let's say, something like, watermelons, For this season, since summer's coming up, that would be a huge one. Maybe it would have a higher turn rate, or think of something like an impulse channel, which is going to have a pretty high turn rates, all year round.

That's what I would focus on, is how can I get more products to store so I'm not constantly having to generate orders. Or you can go for the option of smaller pack sizes. That's going to give you more re Flexibility on replenishment, sometimes you can be a little bit more agile, and the downside can be that the vendor will pay more per order just because there's additional touches and freight charges, but sometimes smaller pack sizes are great to have, especially if you really just need to get product quickly to a store rather than having, something larger that goes to different places in the network.

That's a little bit about strategic pack sizes. And then we would be remiss if we didn't mention RetailReadyPackaging or it's often referred to as RRP or SelfReadyPackaging. So that's another version of how you can be strategic with your pack sizes. So thinking about how you actually package your product, your retail products, what a supplier, a customer would buy.

So that there is no external packaging, essentially a store associate just opens the palette or however it's shipped and then they pull something out and usually there'll be a tear away, on the cardboard, like a perforated cardboard, and then they can set something into the shelf and it's really easy to just set and then and so they'll have no external packaging and be very minimal for handling.

Some of the questions we've gotten about retail ready packaging is why, besides the ones that we have listed here, which I'll go through is there have been initiatives with Walmart that, direct suppliers to you retail ready packaging. So some of those are cutting down on labor costs. It makes it a lot easier for store associates to just, Go in, understand how to set up the product.

And really they're not having to do too much work or, thinking about how something needs to get set up, which is nice because we all hate it when we have this great new innovation or a new SKU that we're selling in, and then you go and look in the assortment set up incorrectly. That's always frustrating.

The other part is it reduces packaging waste. something that Walmart has been talking about for several years is Project Gigaton. That is how they reduce some of the waste and be more environmentally conscious and sustainable. So it's helpful for that. You're not using, three or four boxes to just package cardboard on cardboard before the product is actually visible.

It also helps avoid stockouts. So when you have a RRP. You often know exactly, you will know exactly how many units are in one box. And so it can help, manage that inventory a lot better. And it's also going to just enhance that product presentation. you've all been on to a shelf where you see something that's packaged.

It's got, extra branding. Sometimes it's even got either a QR code. It's a great space for, your marketing teams, your, branding teams to elevate the customer experience. All right, so there's always going to be rules when it comes to pack size on shelf and why RRPs or, however you refer to them, PDQs is another way that they can be referred to.

You want to make sure you're utilizing them correctly. So Walmart's rules with using these retail ready packaging is that there's always two that can fit on a shelf. this is because if And you'll see as we walk through this, the retail ready packaging will usually have kind of one level associated to it.

So saying basically if you see that one is out and you are only selling in one of these retail ready packaging, there's no product on the shelf. So that's why it's great to have two on shelf. So one can just be pulled forward. on the shelf, and then it automatically will know, you will know that you'll need to replenish it.

And then you can always work with the teams if it makes more sense to have more on hand, etc. But it's a much more, fail safe way to make sure that retail ready packaging is, not completely, Out of stock. And then if you're not utilizing those, RetailReady packaging, the expectation is that you build a maximum warehouse pack size that will allow you to fit one and a half warehouse packs on the shelf.

So taking your smallest unit and building up from there, but essentially you want to have one and a half packs on the shelf because if you're only sending one warehouse pack to a Walmart, which is pretty standard for what happens. if you've got four, you'll send them to the four, you've got four warehouse packs within your vendor pack, you'll send like usually one to a store.

So with that, it's great to have it built out. So you have enough safety stock to kind of combat. If there is, one that's completely sold through, you still have that basically half a warehouse packs that's living on shelf. And then when a store sells through that, that one warehouse pack, like I said, it's automatically triggered in your replenishment system for a new warehouse pack.

So it can just give you that, that safety of not having a complete stock out on the shelf. And then this is if you're a visual learner like me, how you would break it out. So reiterating, if you have a retail ready packaging, you'll want to have Two of those on shelf. Makes sense if someone said, you know what, I'm just going to take the whole one home because I love this product so much.

You still have something displayed and it cannot be automatically triggered. And then again, this is a good way to think about that pack and a half, pack and a half rule is, if a pack is six, you want to make sure that they have. That half as well, because if you're selling through this is enough inventory to get you by.

Maybe not depending on, your turnover rate. selling through is, a good problem if you can replenish it pretty quickly. So making sure that you have that state, that safety stock on hand as well. All right, last things on just how you can package those. So this is the, another example of that retail ready packaging fitting back to back on a shelf.

And then if one were sold through. you've still got that one that can then tide over sales until the new, retail ready packaging arrives. And then here's another example of those pack and a half rules. So you've got the six units that fit on shelf. So we can break down this example.

This math can sometimes be confusing. If a warehouse pack is six and you need to divide it by one and a half, you'll want to have at least four units on shelf. So that will be the pack and a half. So you want to make sure that you're able to fit six on shelf, and so that when it's re when it's sold through, you have that trigger that allows you to know that you're low on inventory and need to replenish, at the right point.

So there's no errors and there's no stockouts. All right. So we're, we've talked about pack sizes. That's the first building block. Let's say we've got a great pack size. We feel good about how we're packing our product. We're not having any issues with inventory. let's focus on the other element is how we actually get that inventory to stores.

And let's talk about shipping method. So the first one we're going to talk about is LTL or less than truckload. And what does that mean? It's basically what it sounds like. So with LTL freight, you're assuming that the supplier's only paying for the space needed with freight. And typically it's going to mean that your, inventory is weighing anywhere from a hundred to 5, 000 pounds.

So similar to if you think about a plane, it's really important for, transportation companies to know exactly what you have on the truck because it can affect the journey, from how long it takes to get there. if let's say you, your pallet is, you write down that it's only a hundred pounds, but it's actually 5, 000 pounds, it's going to take up way more space in the truck, which could push someone else's inventory out, which could create an issue.

it could be damaged. It could take the truck longer if they think they're, only hauling something really small, and they're trying to deal with the issues that have come from that. So it's really important to make sure that when you're working with less than truckload or full truckload that you're being specific to these requirements.

So LTL, FTL, Parcel, all of them are great options. It really just depends on what you need, specific to your business, to the expediency you need, things to get there. Not necessarily an issue with LTL or FTL, but sometimes there are, some timing issues, some other things about just picking those.

It can be your category, it can be, the 3PL that you're using, any subcategories. specifications of your product. So we'll get into some of those here in a second. But with LTL, this might be the best option for you if you're looking for cost effective shipping. So you know that you don't need a full trailer, you don't want to have to pay for a full trailer if you only need like a fourth of it.

You can split that cost with other retailers, or other suppliers rather. It's a little bit more flexible on delivery timing. So if you don't have to have your product there at a specific time, or let me reword that. If you don't have to have your product there, With immediacy, let's say, it's getting packed and it'll get there within your MABD window, perfect.

But if you need, if the store needs the inventory tomorrow, LTL may not be the best option for you. So it can really just depend on the scenario. And then the last part is making sure that as a supplier you can accept that slight risk that there may be damage or misplacement. we have had suppliers literally take pictures of stuff getting packed into trucks.

FTL and LTL, it's not necessarily one or the other, just because if you're with LTL, you're going to have people entering the truck to put more product in. And let's say you're the first in, there's, there may be two, three, four times where the truck is getting loaded. And things can happen. hopefully nothing nefarious someone stealing something out of the truck, things can get moved around or bumped.

So if you can accept that risk and you feel okay with that, as well as some of the timing, because there will be other pickups along the way, that may be a great option for you, especially if you have a little bit of product and looking to save, be a little bit more cost effective. All right, what's full truckload shipping?

It is exactly what it sounds like. What, FTL Freight assumes is that you are paying for the whole truck of only your product weighing about 2, 000 pounds or more. if you're interested in FTL, what are some of the reasons why it might be the best option for you? Fast shipping is one. Not to say that, It's going to be, it can depend with collector prepaid and the scenario going on, but you aren't having to stop to pick up other suppliers products or your 3PL or the trucking company, the transportation isn't doing that.

It gives you lots of volume. so if you have Let's say it's, it's summer and you sell beach balls and maybe you need a full truckload to, just meet the demand that it's being asked. other options are, less handling. So you're not having people coming into the truck as many times. It's getting load.

Once it's happening at your receival center or your warehouse, so you really have a little bit more control in that aspect of what, the product looks like once the doors are closed. and that can be helpful when it comes to disputing if you have full truckload, but again, both are great options. And then what's parcel shipping?

So package shipping is basically what it sounds like. We're all very familiar with it in the age of online shopping. It's for that smaller, lightweight individual shipments. It's typically going to be less than 150 pounds, and it's going to be delivered by carriers like FedEx, UPS, USPS, etc. This would be a great example if Let's say you're in the jewelry department, you only have 16 small SKUs that you're sending to stores, and maybe you're direct to store, so you want to ship it that way.

That would be a great example of why maybe you would go with parcel shipping. just to break down that example, the best options for suppliers who are looking for, for parcel shipping would be options to ship individual items, Could be an option if you really need to get something shipped into a store immediately.

Obviously not a good long term strategy to be shipping something directly to a store and then copy pasting that for the hundreds of stores that Walmart has, but it's an option. It's good for online only or DSV suppliers. That's typically, what they're using. And then what, something to note here that can be a disadvantage is that high risk of stolen or damaged products.

We, have all experienced that being in the age of online shopping or, the age of Amazon or walmart. com. It's just, it's going to be the name of the game. So making sure that you feel good about that risk and maybe having additional insurance, or something to Make sure you're able to track that product or make sure that it's received without being damaged.

So another disclaimer there. All right, so we talked about full truckload, less than truckload, and partial shipping, and I alluded to collect and prepaid. It's another option that you can layer on top of, you've got your pack sizes, you've got your packaging, you've got your palette, that's good to go.

You're thinking about, okay, I only have X amount of products, so maybe I don't need a full truckload, or maybe it makes sense to ship direct to store, or I need, just a cost effective way to ship my product, but it's not a lot, so I'm going with less than truckload. Now let's layer on collect versus prepaid.

So What does that mean? We'll start with collect, right? So collect and prepaid are the ways that your product is being shipped, the shipping method in terms of are you owning that process or are you asking someone else to basically represent your product in that transportation process. So CollectFreight is where Walmart backs up to the supplier's facility to pick up the product.

Walmart is using their own fleet or they're contracting with a third party logistics or 3PL to do that pickup on their behalf, and Walmart is taking ownership of that product at the supplier's facility. And then the difference here is prepaid freight. So prepaid is saying the supplier is responsible for delivering those products to Walmart facilities.

That can be a distribution center, fulfillment center, or store. And a supplier is contracting that 3PL to do delivery on their behalf. Some suppliers, oftentimes it's usually your beverage. a good example is I think Frito Lay has their kind of own distribution center and they even go into stores and set up those shelves.

So that's an example of, they are probably, use prepaid freight when they're doing that or have some kind of 3PL. So the difference here is, Suppliers are saying, I'm still owning that responsibility of transporting my product from my warehouse to where Walmart has asked me to deliver it on time and in full, whereas Collect is saying, Hey Walmart, I'm going to be ready for you to pick my product up, and it's going to be the right amount, and I'm going to have everything ready for you, and then once it's in your hands, I want to deliver it.

I'm handing over that responsibility to you as, to deliver my product where it needs to go. with prepaid, you are really, as the supplier, owning that all the way up until Walmart takes ownership of the product at their facility. So you're in charge of, how the product is on the road, you're all the way until Walmart receives it and it's in their DC.

And then you're basically handing over that ownership. And both collect and prepaid are great options. And honestly, most suppliers. Do a mix of both. especially some of those larger suppliers, they're going to do a mix of both. The pro with Collect is that you're not responsible for the delivery performance and freight costs are out of your control.

So you have that going for you. However, you're not in control of those on time deliveries. So sometimes you don't have the full picture of visibility of why things don't get there on time. and that kind of goes to the second point is there's less visibility into transportation. With prepaid, the, pro of using prepaid is that you do have that control in terms of cost, you have a little bit more flexibility to switch to other 3PLs to change processes because you are owning that, whereas with collect, You are hands off, which can be good or it can have its consequences.

And then prepaid, one of the cons that we see is that liability. So you have a lot more responsibility when it comes to on time and in full, and some of the other fines that can happen just because you're handling along that process. But both Collect and Prepaid are going to, have the opportunity to be hit with deductions, AP deductions, OTIF fines, SQEP fines, so it really, there's not a difference there.

And then the last thing, I think I alluded to it a little bit, but with Prepaid, the con is that the liability is yours. You're owning the damages, delivery time, etc. but really bulk, collective, prepaid, or it just depends on what your business needs, and how it operates. All right, we're going to talk a little bit about shipping documents and avoiding those deductions and fines.

so as you can see, we're laying or layering on when it comes to some of those shipments, those shipping, that shipping information at Walmart. You have your pack sizes, your packaging, the way that you're shipping, the method. So now we're going to talk about some of the shipping documents. And how those really integrate into proof documentation when it comes to avoiding deductions and fines.

All right, we're going to talk about, and I've alluded to these, some of the types of shipping deductions and fines that you can receive.

Okay, the first is short shipping deductions. And we'll get into those particular codes, but we do, at Walmart, they have about 70 codes that they're usually using regularly with AP deductions. Danielle can send our AP deductions guide in the chat. If you're unfamiliar with Walmart deduction codes, I'd definitely give that a read.

It's free. it really just goes through what type of deductions are out there, what proof documentation you need to dispute, etc. Today we're only going to go into a couple that we see pretty often. The other bucket of revenue loss that can happen is OTIF finds. So that, to break down OTIF, is going to be your on time.

hey supplier, did you get the full inventory that I asked for on time at the time that I requested it? And then that IF, that in full, is going to be the right quantity there too. And then a newer program that we're seeing, I think it's been around since about 2021, is the Supplier Quality Excellence Program, or we fondly refer to it as SQEP, and you can receive fines from pretty much anything from PO accuracy, to overages, to labels, to packaging, to pallet fines, which I mentioned earlier in the hour. and there's another phase that is coming out that hasn't been released yet. and we'll see if that, that ends up releasing.

We've been holding our breath there for a little bit, but it's on scheduling and transportation. So you can start to see how these deduction programs, which are separate, can start to layer on top of each other and create issues. And a whole lot of fines for suppliers. And I knew this slide was coming up, but this is really just illustrating my point.

These fines can stack. So on one PO, you can get a short shipping deduction, you can get a SQEP fine, and you can get a no tif fine. Just because these programs don't talk to each other, it's not, intentional. It's really just the system. being huge and it can, these are hitting at different times as well.

So it can be a timing issue as well. So saving proof documentation. I'll say that today, but I'll say it now here. you may get on one PO a short shipping deduction and you dispute that and win it. And then a month later you could, get your OTIF fines coming in and you got an OTIF fine on that PO too.

And that proof documentation for the short shipping deduction could be disputed. use to dispute the OTIF fine. So you want to make sure you're saving that. But the impact to suppliers of this is not just the headache of having to go in and dispute and Different portals and different compliance programs.

It's the impact of cashflow. so it can really be, these are all calculated differently, how you're getting a deduction or how you're getting that fine. for SQEP, there's a multiplier. OTIF has its own rules. It's 3 percent of cost of goods sold. And then short shipping deductions have their own, impact.

Calculation for what's getting deducted off your invoice. So it can really impact you at different levels too. And it can depend on the amount of cases affected as well. So you want to make sure that you're, All right, let's get into a little bit of those short shipping deductions I mentioned. These are the ones that we'll mention today.

The reason we're mentioning them is because they're related to shipping. They're also the most common and they're usually what we see suppliers having the highest dollar amount and count amount when we're analyzing their, revenue loss. Really quick call out, we're not doing a sales pitch or, we're not even showing the product today, but we do a free analysis.

So if you're ever curious, I wonder how many code 22s I could go dispute, but multiply that to all the codes that Walmart has. We actually do a free analysis so we can show you that. All right, back to code 22s, 24s, and 25s. These are your short shipping codes. essentially all of these are going to be about the quantity of the item.

Code 22s are going to happen when a quantity of an item doesn't match what's on the invoice, whereas a code 24 is going to be when a shipper invoices for more than what it claims to have received. So it's going to be an overage, which is something that you can get in the SQEP program as well. So you'll see that layering start to happen.

And then code 25s are when Walmart claims to not have received any merchandise. So this could really layer on top of an OTIF find as well, saying, hey, I didn't receive. The product on time because I received nothing. I, the truck showed up and it, the product that you said was going to be there wasn't.

So you can see they're, helpful in terms of understanding what happened in the supply chain, but they can be frustrating because then it's on the supplier's side to start digging in, understanding what happened, and then go and dispute that. All right, we mentioned a little bit of OTIF finds and want to call out that these have changed recently.

Danielle will send the update, OTIF article that we wrote. I'm making Danielle work a lot today, sending all of our resources in the chat. So Walmart's actually changed this. It's reduced down to, I believe, actually it was 98, and so now it's down to 95. So this is correct. Walmart expects a 95 percent fill rate on any non compliant cases, are going to be liable to OTIF.

So that's a 3 percent cost of goods sold on any case. So you can see how that can start to really add up. and what we've seen with suppliers is usually they're really great at Understanding their fill rate, and it's not the majority of their assortment, it's a lot of times those ones that are out of process.

Maybe it's a shipper with, a new assortment. Really honing in on some of those item levels, which is, another thing that's important for suppliers to understand is like, where is this issue happening? Is it at the item level? Is it at the DC level? Digging into that root cause. and just to call out separate from, just the fine itself, deductions are disputed internally in retail link.

OTIF fines are outside, they're disputed outside of retail link in high radius. and then just toggling down to saying, Hey, okay, I'm a supplier. I have these, what, can I do to avoid them? And what can I do to understand them better before they get to that deduction or that, fine situation where I'm actually being asked to pay these back.

One thing we've seen suppliers struggle with is just the forecasting sales to anticipate what Walmart needs in the future. I know that seems basic. I know that's a. key part of being a supplier, but adjusting to, those needs, being proactive and then over communicating is really key. if you're seeing these issues, making sure that you're finding solutions and bringing those and applying them to your forecast or, just communicating, hey, I don't, have this.

inventory because of a supply chain issue at my manufacturing, plant that's overseas. Communicating that as early as possible is going to save you so much headache of trying to, make something that's, just not going to happen. So being proactive and over communicating is those best practices with your OTIF program.

And then the second part of OTIF fines is that on time. So Walmart expects the 90 percent prepaid on time and 98 percent collect ready, which makes sense because they're owning that collect process. And it's still going to be the same 3 percent of cost of goods sold. Walmart has written in documentation that They often try to just charge for one or the other, so that on time or in full.

but if you are seeing both, you may be able to negotiate and say, Hey, I've already received the fine for this. That's written in their documentation, but it could be subject to change. And then here are some more best practices when it comes to both collect and prepaid when it comes to being on time.

So for prepaid, that means you're owning that process. If you want to, deep dive and have someone just explain your delivery window to you, we are happy to do that because it can be a little bit confusing. and we may have a slide on those particularly, but knowing when your must arrive by date is, You don't want to send it too early and you definitely don't want to send it too late.

You're going to get dinged with an on time fine either way. So just making sure you're in that window. And working with your 3PLs for being on time. Pardon me. If your 3PLs are not compliant, you've worked through processes, it's time to change 3PLs. Especially if you're seeing problems with specific, just chronic issues that you can only contribute to your 3PLs.

Or even saying, hey, We want to continue to work with you guys, but something has to give. If this is your responsibility, we'd like to work out a way to pass on those fines to your prepaid, those who are, who are representing you in your prepaid, transportation. And then with Collect, make sure the POs are ready for pickup.

It reminds me of kids who aren't at the bus stop when the school bus comes and they're just running after it. With Collect, if your POs aren't ready, Walmart Collect, Freight, or any 3PLs representing Walmart Freight will leave. They have their own schedule and they want to make sure that they're adhering to who they're ultimately representing, which is Walmart, so they will leave if you are not there Ready to Be Received On Time, because they've got other things to pick up and got a schedule to run on as well, so make sure you're ready. And then, another key thing, and this is an issue we see a lot of suppliers make, is routing those PMs by 4pm Central the day after receiving the order. You want to make sure that you are on time with Walmart.

And another layer of this is if you have your, I forget the specific name, but like your closeout dates. So when you are not picking up, let's say it's a Saturday, it's a holiday, make sure that you are documenting that there's a process on Walmart, on the RetailLink portal that you can close those out.

Because if you should, if you don't close it out and you have orders that are landing on those days, A truck will come to pick up your, product, your inventory on a Saturday or a Sunday, even if it's closed, because that is how the system will set it up. So make sure you have those closeout dates where your, facilities are not open so that the automatic system won't schedule any pickups on those days.

All right, let's talk about SQEP finds. So this is a newer compliance program. really how Walmart has talked about it is it's improving shipping through the Walmart distribution network and trying to get. to 100 percent efficiency, and it's built out in four phases. Excuse me. So that first phase, I've talked about PO accuracy and ASNs.

Actually, Walmart just updated something on their ASN. We talked about it in our newsletter, so if you're not subscribed to the newsletter, that is where we're trying to put. are the content that's coming out really fast. what I'll say is go check the RetailLink portal, they have a news document. if you can't find it, we'd love to send it to you.

But essentially with EDI, there's going to be a little bit of a new process. So you want to make sure that your EDI is set up correctly for Your ASNs, and if that all is, a whole different language to you, we can talk through that as well. Happy to talk through more. Second phase is barcode and labeling.

So you can see where pack size and item setup really come in, to play and can, if you're not set up correctly, can be an issue down the road. Phase three is load quality, label quality and packaging. And then phase four is actually not released yet, but it's going to be on scheduling and transportation.

The nice thing about SQEP. is that these finds are actually disputable in high radius, just like OTIF. So you can go in there and dispute both of those in one portal, even though it's outside of RetailLink. Alright, so we're getting close to time, so I'm gonna go ahead and talk through these really quickly.

But these are the common shipping documents that you're used for disputing, so we'll talk through these here in a second.

The Bill of Lading is a legal agreement, it's a receipt, and it's a title of goods for each PO. And it has important information that can help with your disputing process. It has the quantity and packaging of the items, it has the party responsible for the payment, it has special instructions or additional information.

Has written descriptions of the item, the weight and the dimensions, and the pickup delivery locations, including hours and contact information. So this can really be the smoking gun. BOLs and PODs can be extremely helpful when disputing at Walmart for short shipping, for OTIF, and for SQEP. Really just depends on the specifics of the code.

But this is what we will point suppliers to using if They have access to that. And then the last is the POD. That's going to have your ship to address, the purchase order number, some of that basic item information, which can be helpful to point to. And then the warehouse store stamp showing received in full, which is extremely important to get.

And if that's not happening, that's something that you can bring up, in your process to make sure you're getting that, because it can be really helpful proof documentation. And then a caveat here is if you're shipping collect, You're not responsible for providing this document, and you have other means to dispute, besides a POD if you're needing proof documentation.

some best practices with shipping documentations is do make notes of the damages, on the POD or BOL, training your team or the 3PL that you're working with to do that. Ensuring your product's, replacement value. When you're disputing, Walmart is going to deduct for the retail value, the cost for them, not the value of the product.

They're going to dispute at the highest cost because they're the ones that are selling that into the store. Sorry, all those allergies are getting to me. And then last thing is follow the proper packaging guidelines. Again, I called out the secondary packaging guide. We have a cheat sheet on this if you want the high level details that are really helpful for suppliers, but it is important if you're seeing chronic issues to review that, dig in, see what maybe your team is doing.

doing incorrectly and then going from there, making a game plan. Another, on the other side, the don'ts are don't sign a freight shipment without inspecting. this can leave you in a hard place. Don't leave BOLs unsigned without documentation. Getting those BOLs signed, that can keep suppliers on the side of, it says on the BOL that you received all of it, so maybe there's a different issue and disputing that way.

And don't wait to dispute a damaged or short shipment, doing it in a timely manner. I know that suppliers get a lot of these pretty often, but making sure that you're disputing that because it's harder to track down proof documentation with. BLs and PODs, some 3PLs will erase those after a certain amount of time, just for storage purposes.

And Walmart only has, 13, they only save 13 weeks back of rolling data, that 14 week gets cut off every time, again, for data purposes, just saving storage space. as soon as you are able to dispute something, you want to make sure that it's, Timely so that you are, getting the most accurate and the most, information that you can access at that point.

Alright, perfect. we're at the q and a part. I'll go ahead and check in with Danielle if we have some questions. I know I talked all the way to two.

[00:57:15] Danielle: You did a great job. Thank you so much for going through all that content, Ali, and thank you, everybody, for joining us today. It looks like we didn't have any questions come through.

I'm still going to keep an eye out for that, but in the meantime, if you think of a question later or would like to share any insight, please feel free to reach out to us on our email. It will pop up on the next slide. or if you don't, if you're trying to find more people, you can find us at supplypike.

com. We would love to continue that conversation with you. But that is all we have for you today. Our next webinar is going to be next Tuesday, and that's going to be, Retail Link Apps for SQEP. So we're just going to Go through some RetailLink apps that can help improve your SQEP performance.

So you can find that webinar registration on our website. So we really look forward to seeing you there. Thank you guys all for joining us today. We hope you have a great rest of your day.

Hosts

- Read More

Allie Welsh-Truong

SupplierWiki Content Manager

Allie Welsh-Truong is an NWA native with a background in the CPG industry. As Content Manager, she develops and executes SupplierWiki's content strategy.

- Read More

Danielle Gloy

SupplierWiki Researcher

Danielle is a Content Coordinator at SupplyPike. Her supply chain degree helps inform her research and writing on SupplierWiki

Presentation

Walmart Shipping 101

Access the Walmart Shipping 101 slide deck to find everything you need to know about successful shipping practices with Walmart.

Related Resources

Sponsored by SupplyPike

About SupplyPike

SupplyPike makes disputing OTIF fines easier and faster than ever. This tool gives you insight into projected fines before they hit your bottom line and allows you to dispute invalid fines in just one click.

About

SupplyPike helps you fight deductions, increase in-stocks, and meet OTIF goals in the built-for-you platform, powered by machine learning.