Amazon Shortages and Price Claims

Transcript

[00:00:00] Allie: Today it's going to be me and Shawn going through today's content. So Shawn's going to be leading this. Shawn has a wealth of knowledge when it comes to Amazon. He's been almost on every side of the business, including working with Amazon in the past. And he is our Retail Insights Manager here at SupplyPike I'll be teeing up questions and sending any resources in the chat.

And my name's Allie Truong. I work on the SupplierWiki side. So I'm writing content and putting decks together for suppliers like you. So we're glad to have you. To go through today's agenda, We've got a packed agenda. please feel free to ask questions and engage in the chat. What we're going over today is first shortages.

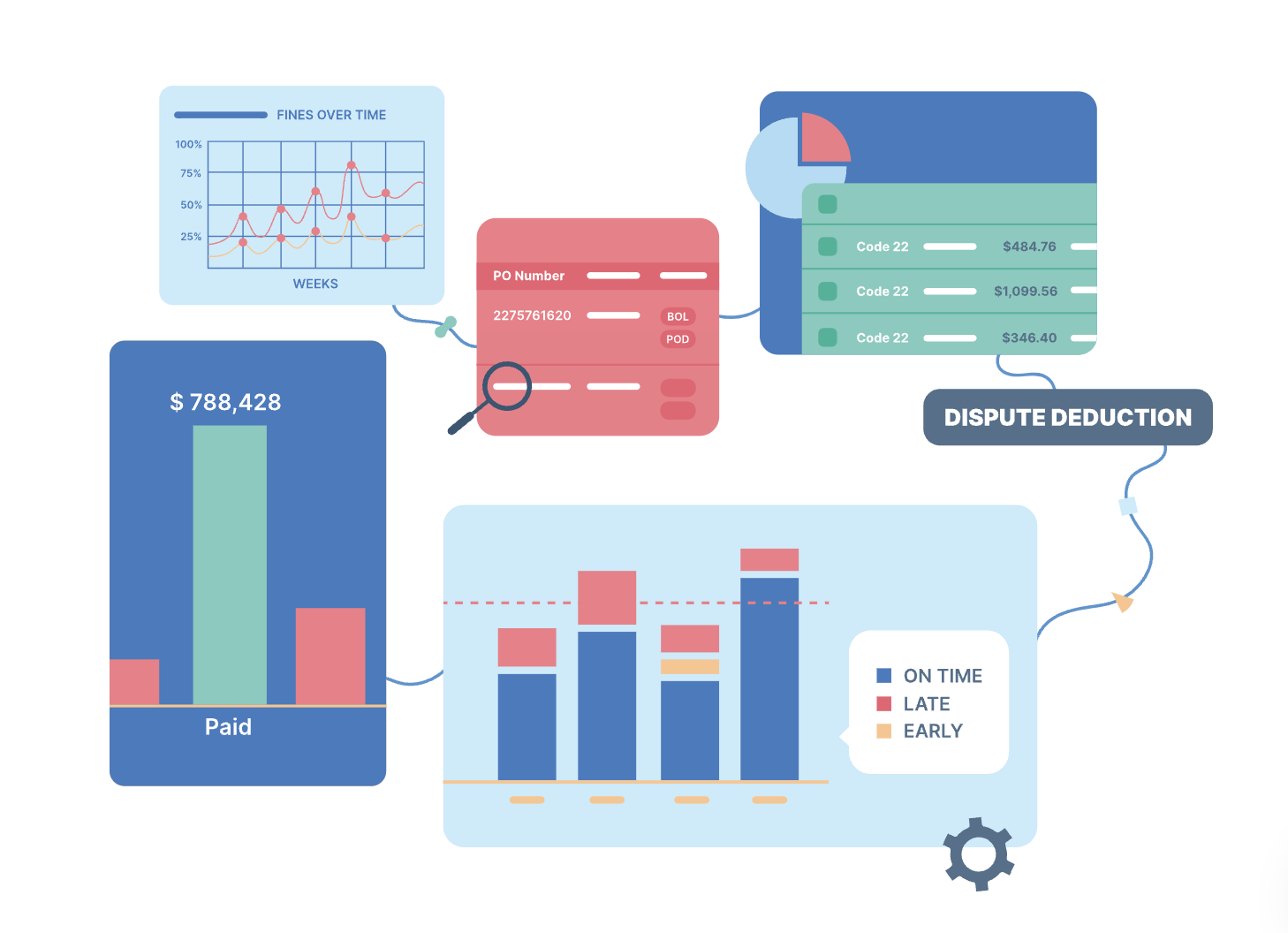

So we're going to talk about what a shortage is at Amazon and how you can dispute those, and then we'll transition into price claims and talking about how you can dispute invalid price claims. And then towards the end, we're actually going to have a quick Q& A with Shawn and I. And, want to call out that at the end, we will also have a quick product preview of what SupplyPike can do for your Amazon shortages, and other revenue loss areas.

So stick around for that. Couple of FAQs that we get on every webinar is, will you get a copy of today's slide deck? Yes. If you're ever on a SupplierWiki webinar, if you sign up, we are always going to send you the slide deck and the recording to your inbox in about three to four business days. We usually get it sooner, than that, but we wanna make sure that we get you guys the quality recording as well as a PDF version of that slide deck.

And then our last FAQ is what is the best way to ask a question? So you'll see the q and A tab on Zoom. That's actually the easiest way for me to see your question. It's got two speech bubbles on it, and those kind of stay there and are held so I can read all of the questions. You can put them in the chat.

They might get lost if we get a lot of engagement or I send a bunch of resources, but that's actually the best way to engage with a group. Sometimes Shawn or I may ask a question to the group of, you know, what's the, deduction that you're seeing the most at Amazon. We want to hear from you guys. Cause this is a great place just to learn from other suppliers.

So we're glad to have you on here today. And on my next slide, I'm just talking about who SupplyPike is. So if this is your first webinar, hi, we're happy to have you. we're SupplyPike. We create cloud based tools that help CPGs reduce revenue loss. And we do that in a couple different ways at a couple different retailers.

today we're talking about Amazon. But we do have solutions at Walmart, Target, Kroger, and now Home Depot. So that's really exciting. It's a new retailer that we launched just this year. today we're going to be focusing on shortages in price claims, but if there is a revenue loss area that you are experience, experiencing at Amazon, this is a great webinar to talk about that.

Shawn has a wealth of knowledge on some of the compliance and chargeback areas as well as co ops. And I'm probably, leaving off a myriad of other ones that we could talk about today if you have additional questions. Last thing I'll say on this slide before I hand it over to Shawn is that we work with a ton of retailers, across product categories, to help Solve some of those compliance issues and, you know, catch root cause as well as, dispute and help win back, those recovered dollars.

So if you don't see your logo up here, or you haven't worked with us in the past, we'd love to help get you connected to our team that works on that. But for now, let's get into today's content. I'll hand it over to Shawn here to start us off.

[00:03:44] Shawn: Perfect. Thanks so much, Allie. Okay, so like Allie mentioned in the agenda section, we're going to kick things off with shortages. And honestly, we're going to start with some of the foundational stuff, just to, again, set the scene, make sure that we're all on the same page, got a good footing on what we're going to go through today. So, as far as just the broad definition of what is a shortage or what is a shortage in the eyes of Amazon.

Shortages is simply a mismatch where the item quantity on the invoice does not match what Amazon says the fulfillment center has received. Another way that you might see this if you're working with Amazon is called a PQV or a Purchase Quantity Variance. Amazon definitely loves their acronyms, so expect to see a lot more of those both through the rest of today's presentation, just in general as well working with Amazon.

But again, look at a shortage simply as a mismatch. and the visual example here is a good example where we've got six units on your invoice. This is what you physically shipped. Amazon claims that they've only received three of the six units.

There's another key thing to understand with Amazon, and it has a lot to do with timing. So there are a couple of different types of shortages at the end of the day, at least how Amazon is viewing this. So this is a key thing to keep in mind. This is kind of how Amazon is viewing things again, and it's very time bound, essentially on a timeline.

We could look at potential shortages as signals upstream that are indicating to Amazon. That there is a strong likelihood downstream of there being an actual shortage or some type of missing inventory. This is usually again, due to a timing issue. So upstream signals prior to the due date on your invoice.

But, Amazon, again, is looking for signals upstream, potential, PO confirmation updates, shipping updates, any sort of indication that that shipment, how it's routed, previously or as indicated, initially as scheduled has changed or been updated over time. So, this is where Amazon's going to market, in their system as a potential shortage.

It does have an opportunity, of course, to be matched later or to become a true shortage, depending on if the inventory actually arrives. this is more of a warning or an indication, again, that there's going to be some type of downstream issue once the due date on your invoice for that shipment actually comes to date.

So the middle section here, as far as the section between the potential versus the remaining, is essentially that Line in the sand or the line on the timeline that corresponds with the due date on your invoice. And if at this point in time, the quantity, does not match, this is where it's going to turn from a potential to an actual shortage or how Amazon views it is a remaining shortage.

So this is any time where again, quantity doesn't match what Amazon claims that they've received. And this is high likelihood, this is the result of a. unresolved potential shortage. So, AKA, there's been something that's actually gone awry in the process on that timeline, in between that shipment going out the door from your, warehouse to Amazon's fulfillment centers.

them cracking open the boxes, receiving all the goods by the invoice due date. So again, there's something that's happened in that process where Amazon hasn't been able to correctly receive or, count and attribute the inventory to that shipment or to that order. So they could not match those units.

Therefore they couldn't pay you for those units. And again, it's just because of. Some type of defect that could have occurred upstream, whether that was in your process or potentially in Amazon's receive process as well. So we'll unpack that a little bit, but the timing element with Amazon is pretty key to understand as well.

So this is really important again, because, understanding why shortages occur can be somewhat complicated just due to the nature of the supply chain and how many steps and processes are ultimately involved. in between the A and the B of your warehouse and Amazon's fulfillment centers. so I will say that this list or the list and the points that I'll go through are, are by no means exhaustive, but they're most frequently occurring issues that we see, in working with vendors and suppliers that are doing business with Amazon.

so again, if we're looking at the whole end to end picture, with Amazon and the PO lifecycle. The furthest point upstream that Amazon is receiving information from you about your products is going to be in your product catalog. So this has to do with your item setup and occasional maintenance of the items and their attributes.

So that'll be things like your size, weight, dimensions, the cost, the price. of course there's many other attributes that you can include an update, but as far as some of the things that will impact and affect shortages, those are some of the key bits to be aware of. It's a lot of the shipping information as well as some of the stuff with the cost or the price.

But, errors upstream in the catalog and item setup can absolutely cause issues downstream. if you tell Amazon that you've got 100 units in a case when you only actually have 10, again, you're going to have some problems with how Amazon's receiving at the end of the day, or at the very least with how they're ordering.

From you initially. but again, that's the broad concept there is that issues upstream are going to flow and continue to be issues downstream. So ensuring that your catalog is clean and up to date, it's really important. so that's kind of square one or step one that we say, why might a shortage occur?

definitely double check or scrub your catalog, make sure that all of that shipping and item information is up to date and accurate. the next thing is going to be. Forgetting the ASN or submitting the ASN with incorrect information. So more acronyms here, the ASN, excuse me, the ASN is the Advanced Shipment Notification.

It's more or less, a virtual BOL or pack list that gets submitted to Amazon so they can adjust that information to their system, automatically know, what they're expecting to receive in their fulfillment centers any given day, any given time. So, if you forget to send this virtual signal to Amazon, again, there's no way for them to know what to expect, when to expect, and it's also a crucial piece to their automated receive process, which is primarily how they are able to receive so many goods, into their fulfillment centers at any given time.

So. If you've ever seen videos of Amazon Fulfillment Centers, it's like a madhouse in there. Tons of different trucks, tons of different shipments, lots of conveyor belts, robots, all that good stuff. So again, giving Amazon the proper advanced shipment notification with the correct information about what and when they should expect your inventory is going to be crucial.

And again, in part, because that's how their automated receive process works. So if there's any confusion with that, it basically means that they can't use that automated receive process to receive your goods without cracking any of the boxes, they got to take the additional time, the additional resources to open all the boxes, manually scan and put things into bins.

So, not only just potential room for error, but additional lead time gets packed into that as a byproduct as well. So, there's additional things to consider outside of just some kind of simple EDI transmission errors that could be, you know, impact of forgetting or sending a late ASN. So, more food for thought on that piece of the process.

The next thing we'll talk about is just sending an invoice too early or duplicating the invoice. And the reason this is important is just the matching process that occurs is, is basically, physically matching what Amazon's getting in their fulfillment centers with what you're invoicing for at the end of the day.

So there needs to be ultimately, again, a one to one relationship between what you're physically shipping as well as what you invoice for at the end of the day. So, Why this could cause problems with the timing is if you're sending an invoice too early, if it doesn't match with your shipment, there's a likelihood with how Amazon matches and their automated processes that they'll Incorrectly match units from a different PO to that invoice.

And we see this all the time. I get questions about this pretty frequently. Hey, this shipment's sitting on my dock. Why is Amazon already receiving for it? And it's likely because there's an invoice in the pipeline, that Amazon's trying to match against. And that could be, again, a potential reason there's a shortage, but more again due to a timing related thing as opposed to a true misreceive.

Duplicating the invoice, similar effect, but again it's going to be more where they'll receive half of the order to one of the invoices and half of the order to the other, so they're both going to seem short just because there's a duplication of what you're invoicing for. So that's something that, again, It's going to cause some issues, but it's going to be more of a virtual shortage as opposed to what I would consider a physical shortage.

But again, kind of the timing related things and some of the physical versus virtual elements that are involved in here, you can understand why it's a little bit complicated. to understand why might a shortage occur. the next piece that I'll talk about on this slide before we go to the next is going to be just non compliance with Amazon's labeling standards.

This seems pretty simple, but again, the labels are an integral piece into Amazon's automated receive process. It's basically the link or the bridge in between the physical and the virtual world. And it's what connects the dots between your packages and the advanced shipment notification. So given that you send that on time and everything's accurate, when they scan the label or the carton, barcode on there, they will link that systematically with your advanced shipment notification.

And that's how they'll be able to automatically receive the contents in that carton without ever physically opening it. It's pretty cool if it works, but again, having proper labels is key to make this actually work right. and non compliance with Amazon's labeling standard means that you're not only going to get chargebacks, potentially for those infractions, but your goods are going to get sidelined.

Someone's going to have to open the box again, more room for manual error. Adding additional lead time as well into your goods getting received. So there's a lot of downstream impacts for that. And labeling again is really crucial with that automated receive process and ensuring that that works correctly.

So can't emphasize enough that labels, labels, labels, make sure they're correct.

Okay, so again, not an exhaustive list, but wait, there's more. We've got a few more on here and some good reasons to go through as well. About why shortages may occur. one of them is going to be vendor lead time. It's AKA accurate PO management. vendor lead time or VLT is another, not only great acronym, but another metric that Amazon uses to measure performance of its vendors.

It's not something that I feel like has been on the surface as much as it was maybe, you know, five, six, ten years ago, but it's still something that you can track, in your metrics in, Vendor Central as far as, your supply chain health or some of your metrics there. It's basically an indication of the time in between A and B.

So once Amazon places an order, how long does it take in days for them to actually receive that or get it into their inventory pipeline to be able to sell it? so the fewer days the better, right? the better turn, the better for you, the better for Amazon. so reducing the vendor lead time or reducing the friction in your supply chain, is key and that can also be in part in how you process and manage your purchase orders.

So, again, the way that you're communicating with Amazon is, typically done either via Vendor Central or via EDI. So there's, typically some kind of data communication that's happening back and forth, and that is, pretty crucial in the PO confirmation process. So, they have some expectations with you being a vendor.

that you're going to fulfill a lot of the orders to them as part of that relationship. So ensuring, again, that you're able to communicate back and forth with Amazon consistently with what you're sending them and when you're sending it to them is going to be very key, again, for the timing element to shortages.

So, again, not updating your POs if you're down confirming or cutting lines, but you're still invoicing for them. things like that. these are some sort of issues that, again, not updating information or your confirmation signals to Amazon, or not updating those signals end to end through your PO confirmation, as well as, invoicing steps.

We're going to lead to some problems with, How Amazon's receiving your inventory as well as potentially how you're getting your shortages at the end of the day too. So non compliance with Amazon's delivery window is the next one. This is again more of the timing based shortages where we see Amazon's pretty strict about how they're allocating time in their fulfillment centers for receiving these shipments.

Again, they expect you to jive with their rhythm and with their schedule, as opposed to the other way around. and part of their process is again, pretty strict around ensuring timeliness and getting, these shipment or delivery windows on time. So what happens basically is something goes out of this window, potentially it's going to cause issues with not only their receive process, but.

Also potentially causing issues with the timing element of shortages and how that affects, kind of the downstream with the pay and deduct, is based on your payment due dates. So basically what I'm saying here is that, you know, if you've got late shipments, but you've got short payment terms, you're almost certainly going to have issues with shortages or things that appear like full shipment shortages.

again, this is often due to timing. If you've got shorter payment terms, but you've got issues with getting your Deliveries on time, or again, updating that information to Amazon, you're going to have some shortage issues that are most likely due to timing in nature. Inbound receive process. Receive has to be processed manually.

I was talking about this a lot on the previous slide. We're talking about kind of downstream issues with Amazon's receive process. Again, Amazon is highly automated. You've probably experienced this if you've been working with them long enough. Whether that's just in the nature of how you work with them, or just, how you kind of communicate back and forth with them, even.

So lots of stuff is highly automated and that includes their receive process. So they're basically going to penalize you. if anything goes outside of that automated receive process, you'll see this in the form of chargebacks. chargebacks are basically compliance fines. I know we're talking about shortages.

But I would say in a lot of cases, there are strong correlations in between what you're seeing as chargebacks and issues that could be causing Amazon to manually process or receive your orders. So that could be things that, are due to labeling issues, ASN failures. there's often things that will happen due to, ships in its own container or any of the product prep requirements.

So, for certain product categories, it's pretty strict on how you're, how you're properly packaging your materials or your goods to send to Amazon. It doesn't meet those criteria. Amazon's going to sideline them and they're going to redo all the packaging. All that stuff takes time. So, what I'm saying is that not only are you going to be penalized likely in the form of a chargeback, but the time that it takes to go through Amazon's receive process, again, on that timeline I was describing earlier with the potential versus the remaining, the trigger point being your due date on your invoice.

if things are happening that push it outside of that window of time, past the due date on your invoice, you're going to have a lot of issues that could also, again, be due to timing or any friction in Amazon's receive process. obviously manual processes can have errors or prone to errors, especially at the speed and pace at which Amazon is operating.

oftentimes the, the Northstar metric is a speed over quality with Amazon. So again, if anything has to be processed manually, you know, it's being done as quickly as possible, which is prone to error, any errors in that manual process, Amazon is still going to point the finger at you and say, vendor, you made us do it this way.

So tough, deal with it. You're going to have to dispute. so that's, again, what we're trying to avoid or prevent is anything that has to go through that received process. So they can't point the finger at you for, for that happening. The last one I'll touch on is loss prevention. That's a more rare thing, I would say, from my point of view, that we would encounter, but I will say, Stuff happens, so it's not completely out of the realm of possibility that things truly go missing and go missing after you've already, shipped the goods or basically, you know, delivered, your products to Amazon.

So there's other ways to rectify those types of issues if they do happen, but that could be an exceptional issue why a shortage may occur.

Okay, so now that we talked about some of these reasons, let's talk about ways to avoid them, ideally. So, you probably got some, some good pointers just in the commentary there in the past couple slides about some things that you can do to potentially avoid them, but here's some more specific, ways that we can nip some of these issues in the bud, or kind of more tactically manage ways to avoid these.

So this first line here, or the second one here about canceling invoices, I'll say, is a little bit more of a tactical step and some things that we can do just to clear out a balance in the case that there are any issues. With invoicing related kind of steps or invoicing issues and or stuff that's due to timing.

So we know stuff happens sometimes you've got a shipment stage that doesn't end up going out the door, but you've already submitted that invoice to Amazon. there are ways that you can technically cancel an invoice, even though there's not a, like a cancellation step, what I would say, or my advice is that it's technically called a credit memo on Amazon, or that's the step there.

So it's just a way to zero it out. It's more of an accounting based term, but that's technically how you would cancel an invoice. is by issuing a credit. That's something that you can do if you do spot an invoicing error. For example, you goofed, you made a duplicate, no big deal. You zero it out or you can cancel it by issuing a credit memo.

Similar scenarios can happen where you're not able to actually fulfill a shipment as planned or expected. Stuff happens, like I said, you still can cancel an invoice if you submit it and you have a window of time to do that if necessary. So those are some things that I'll talk about there as far as Again, kind of more tactical things.

If you've, if you've made a kind of an accounting error or you've accidentally issued multiple invoices that you can do. Another one is more of a best practice, and this is just the timing piece that I was saying. Avoid mismatches or potential mismatches, just get the timing right. Timing's big with Amazon, hitting the windows, that they, set out there for you.

This one isn't very clear as far as what Amazon claims, but our best practice is what we see and recommend typically is to send your invoices between one and four days before the actual delivery date of your shipment. That's gonna give enough time. For it to be processed and then again for that shipment to go through and be matched as accurately as, as possible.

I already talked about this when I was talking about your catalog earlier on, but ensuring accuracy in your catalog setup and your, and your item setup is, is, is crucial. if you've got things again, set up incorrectly upstream, it's absolutely going to float downstream and cause more issues. So doing routine, regular catalog maintenance.

ideally quarterly, biannually, at the very least annually, I would say is going to be key, especially for some of your top selling items. and then invoice content must match the PO and the ASN. So this is one I also can't, can't stress enough, not only just in the catalog and what you've got set up with Amazon, but also how you're communicating with them in your process throughout the POA lifecycle is pretty key.

and that is also some errors that we see pretty frequently. It's just, there's oftentimes discrepancies in between what you, what vendors or suppliers submit. on their invoices compared to the PO. so the left hand not talking to the right in these kind of situations, but ensuring that there is a three way match.

and that is going to be in a number of different ways, but, if you've got different SKUs or different ASINs that you're sending to different customers, but, you know, you have them, all the same in, in these, it's, it's going to be key just to ensure consistency with how Amazon is receiving All of your information and your inventory at the end of the day.

So again, ensuring consistency and that one to one to one match between these elements, your PO lifecycle is going to be. Absolutely critical for avoiding shortages.

[00:27:35] Allie: Hey Shawn, we have a question that just came through, and it's about shortage claims, so I figured I'd bring it up now. Eva asks, shortage claims from Amazon for UPS delivery have failed delivery appointments. How would you fight that? for some additional context, Eva says on their website it shows that they received the product, and the support ticket response is that no delivery appointment was made by the carrier.

So there's no return showing for this product, but they're also saying that it wasn't delivered.

[00:28:09] Shawn: Yeah, I think that's honestly something that's probably best to resolve directly with the carrier from my perspective, regardless if you're doing like prepaid or collect. I know that oftentimes you're, you're using, Amazon as the carrier partner or essentially using Amazon as freight network if you're collect freight, but, these type of situations I'd almost certainly try and, coordinate with the carrier to see if there's.

Something we could work out. from my perspective, again, if you're seeing that goods are being received against it, but there's no delivery receipt, it could be again, kind of what I was mentioning earlier about. Amazon incorrectly matching some of the inventory from other shipments and attributing it to that PO.

but I mean, the first thing that I would do is to try and figure out what exactly happened to that shipment. if there's no, again, specific delivery receipt that you can find, or if that's what Amazon's claiming, I would almost certainly try and coordinate again with the, with the carrier specifically to see, what's going on.

If that's still, inbound or if there's a possibility of maybe getting that shipment appointment rescheduled at a later date. Again, there's still the timing issue with shortages that are at play there, but, you know, no longer than the missing delivery or the, you know, full shipment shortage you have to worry about then.

[00:29:32] Allie: That makes sense. just to add additional context and maybe, build on this question. Eva just put in the chat, the delivery status from UPS shows delivered. So how would that change your answer?

[00:29:50] Shawn: Yeah, I mean, I'd say if, if you've got a specific delivery receipt, but Amazon has claimed that Again, they have yet to receive it.

There could be other, other issues at play that are, are causing that. And so, first thing I would do is, is probably, again, get the delivery confirmation, get any of the potential, evidence that you've got that that shipment went out and that was in the correct window of time, and basically use that as your evidence to dispute the shortage claim.

it could also be again due to timing. So it's something that we'll recommend typically as best practices. And a little bit later in the session, when we're talking about how to tackle these is, waiting for Amazon to receive the shipment appropriately, or allowing enough time for them to happen, kind of the dust to settle again, before we actually are able to go through that dispute process.

But, hopefully that helps clarify that for, for for Evo.

[00:30:51] Allie: Yeah,

[00:30:52] Shawn: I'm happy to dig into that a little bit more also as well.

[00:30:56] Allie: Yeah, definitely. All right, I'll let you get to the rest of the content. Thank you, Shawn.

[00:31:01] Shawn: Of course.

Okay, so let's talk a little bit more about how to avoid shortage claims. so like I mentioned, as far as issues that drive shortage claims, one of the things that is a big misstep is not appropriately labeling your inventory. Okay. labels are the, basically the crucial link in between, the physical and the virtual world and how Amazon is able to automatically receive your goods without ever physically opening any of the boxes.

so one of the key things, and this is also a compliance related issue, but. Only one label on your carton or your master pack, and that means no UPCs, on your carton. And I know that this is a challenge for, for some folks and how they manufacture or ultimately package their goods. but again, the way Amazon receives is basically putting all of the, cartons down a laser scanner tunnel.

It's called the parcel identifier. What this does is basically scan all of the sides of the carton simultaneously while also doing a cuba scan, so taking the size and the weights and the dimensions. So it's a pretty crazy little machine, but if you've got multiple labels on there, you fool the machine.

and it can't appropriately read each of them at the same time, so often times what we'll see is the parcel identifier scans the wrong one, and if it's a UPC, sometimes it'll think that's one unit as opposed to a carton of multiple units. And again, that is another thing that is often a cause of shortage claims.

So, verifying the complete shipment as per the freight bill and the purchase order. So again, that's just one of these things about doing a little due diligence and just ensuring that as far as the paper trail or any of the evidence and documentation that you've got about that particular order, if you show that it's been delivered, ensure that it shows that it's been delivered complete, right?

that's another thing too we want to double check and make sure, that as far as that paper trail, it's also telling the same story that you're telling Amazon and nothing different. so this would also include in that paper trail things to avoid. marking your BOL or your bill of lading as SLC or, ShipperLoadCarry.

So this is often something, again, where, basically it's gonna be, putting a lot of liability on you. if you're saying that the shipper did the loading as opposed to, what you signed off on. So, again, avoid marking that to prevent liability for shortages in general. so that's going to be my advice or our advice there.

And then again, this last piece here is going to be like a broken record on my end, but reviewing Amazon's labeling and delivery compliance requirements is going to be absolutely key. This is just understanding the rules of engagement. You're working with them, they're setting the rules. You have to abide by them or else you're going to get the stick.

And, Amazon's pretty, pretty, again, lengthy and, and, descriptive on what they expect from vendors. They provide it, I believe in a big document and it's called their North American Vendor Transportation Guidelines. It's something that you can find in Vendor Central LinkedIn there, and it's something that I believe they also regularly update.

So it's always changing, of course, which makes it tough. But, shameless plug for us at SupplyPike in saying that, you know, we've got a great team that stays on top of all of these updates and changes. So, we're providing you with the latest and greatest things to keep track of and keep tabs of as far as, compliance updates and changes as well.

Okay, we talked at length now about what can cause shortages and what are they, what causes them. How to avoid them. so we're getting down to the piece now where it's talking about disputing them. how do we manage that piece? And of course, one of the important pieces to understand is that of course, Amazon is peculiar, self described peculiar.

And because of that, there are some caveats to how, how things work there. so a couple of these that are key to note and that differ pretty drastically from other retailers that you're probably working with. are going to be that, one, PODs, or Proof of Deliveries, are not a required, are not a required item to dispute.

and this is a real head scratcher, and oftentimes folks don't quite understand this. And I will say that, this is in part because of a change that Amazon's made in their process somewhat recently. it's probably been three or four years now, frankly, but, this, there was a time, when Amazon did actually accept or actually require proof of deliveries, in order for you to dispute a shortage.

I'll explain it from a couple of different viewpoints or perspectives on why they don't do this. and I'll explain it from the perspective of Amazon, right? reviewing PODs and BOLs, is pretty resource intensive as far as what it actually requires to do it and to do it well, right? If you think about it, there's not necessarily a uniform or a standard format for PODs and BOLs.

Oftentimes they're handwritten, oftentimes there's lots of chicken scratch, it's been faxed. It's been scribbled. so again, if you think about human set of eyes having to review these for consistency and accuracy, it just takes a long time, right? And Amazon is all about efficiency and doing things in an automated fashion.

And they think that, again, there's got to be a better way for us to do this. And they think they've found it and they think that they don't need these anymore to achieve the results that are, equal or better in some cases that they would get from reviewing those PODs and BOLs. So basically what they do now is they request specific bits of information, which will include your item codes, like your SKUs, your ASINs, your part numbers, whatever.

they'll also ask for some shipment information about that. So the delivery, timestamps, or when they expect to receive those items as part of that. it's only the pieces of information that they'll get, and that's, again, to help them triangulate where those, items might be in their fulfillment network in order to, again, Kind of apply that correctly.

So that's again, real broad strokes, kind of background information on, on my take on why Amazon doesn't do this anymore. I still will say as an, as another caveat to the caveat is that PODs and BOLs aren't required, but they still might come into play and be useful, credible information at some stage.

in order to dispute or contest a shortage claim. So keep that in mind. Not a required piece, but potentially a helpful piece at the day if it comes down to it, especially in the settlement. the last thing I'll talk about on this as a caveat is that, in that whole pay and deduct that happens with Amazon and shortage claims, you're only going to be getting fined or you're only basically getting, shortages for the items that they haven't received.

Not the entire invoice. so even though they do do the pay and deduct, they're not withholding the whole invoice, they'll pay for what they receive, only withhold or deduct for the short paid items.

Okay. Now that we've talked about some caveats, let's talk a little bit about the actual process here. How does this all work? So, at the end of the day, Amazon is again, highly automated. they've got a notification center within their, within their application in Vendor Central where you can set up and configure a variety of notifications.

So if you configure it right, you'll basically get an email about everything in the PO lifecycle that can go on from end to end through the catalog setup, if anything goes wrong with that, through Order notifications through anything, including shortages. So, you can get notifications set up, to get, emails on a regular basis about these types of things.

So our recommendation is double check, probably got set up initially, and the person might have, set it up is long since gone or moved on from that role. So if you're not getting emails, I'd say double check here, go into the settings and the notification sections, and you can update the, person receiving emails in the accounts receivable section there, and that should be helpful in order to, again, get some notifications about when this is happening, more signals.

about what's going wrong. So once you've determined that there has been a claim, our stance is that it's key to validate whether this shortage claim is truly legitimate or not, right? Amazon's got a couple of checks, ultimately, that they're going to do on their side before they notify you or the supplier of a shortage.

They're going to continue to try and match that in the background for a set period of time. You've probably heard of Amazon's SmartMatch. That's kind of this matching system that we've been referring to this full time. so leading up to the due date on your invoice, if Amazon thinks that there's a shortage claim, based on the signals that they receive, boom, what they're going to do is issue a shortage claim, and then they're going to continue to check.

But again, I'd say there's some due diligence, that's due on the side of the vendor or supplier just to ensure and double check. Is this due to timing? Is there a true gap on our side that's caused a shortage? Did we short ship? Was there an invoicing issue? Basically, let's try and figure out if this claim is truly legitimate or if it's due to timing or, what is the story with this.

So, if we've determined in fact that, the claim is invalid, we have shipped everything in full, no real signals of any compliance related process issues that have happened that could have made the goods be sidelined for manual receive, it's time to dispute. It's time to take your claim to Amazon and, and file a dispute and try and recover and get those dollars paid back.

and inside Vendor Central, within the, Payment section, underneath Invoices, there's a couple different places that you can do this. these little available actions that pop up, these are kind of the quick action buttons that you can select in order to review and dispute shortage claims. It's typically only for like the trailing 60 or 90 days that you'll be looking at your invoices.

but this is one route that you can get there to look at the most recent shortage claims that you would have received. So within this section, this is how you'll be able to go through and review these. And you'll see from the available actions drop down if you select on one of these invoices that there is an option to dispute the shortage by ASIN.

that's where you'll click here in order to actually open up or file a dispute. So if you've done your research, you know for sure that this particular invoice and this shortage claim is, is invalid based on your research. Go ahead and file a claim. Select dispute shortage by ASIN. This is where the real fun begins.

And if you've done your homework, you'll need to input some of that information from your research into the claim. Amazon's going to ask specifically for a few bits of information, which is going to include the dispute quantity. So, Of the shortage claim, how much are you actually contesting? Is it only a portion?

Is it the whole thing? What do you believe was actually shipped and delivered? So tell us more now about the product. What did you actually ship? would it be that you accidentally told Amazon you're going to ship something else, and you sent them a different product, help them identify that, give them some further details or information that's going to help them link back to the catalog and that can include things like your ASIN, the SKU, or some other.

Unit identifier that will help them match that easier. The ship date's important. Again, this is going to help them triangulate in their network. If it's something that they received a little bit later, or it was maybe still in the pipeline, this is going to help them again, better triangulate. Where on earth are these items that they say that we received?

So once you input all that information, there's a couple bits of additional information that you can include as well. this could help improve your claim, right? I would say, in this case, additional information is helpful. We don't want to overwhelm them, so help them, you know, give them bite sized bits of information that will help them to support, support or validate your claim.

And this could include things like, excuse me, your ASN. Thank you. So, sometimes, that will be helpful information for them to, again, better identify when or how many items that they received. Kind of tying, connecting dots back to their own receive process a little bit easier. The other one could be images of carton level labels.

So, again, what do my items look like? What's something that we can use to quickly identify or receive the inventory on their side? Again, just helpful information to guide them along to help validate your claim.

So, there's a couple other things that you can also do, which will include adding attachments and other details here. So the dispute title is one of these things that you'll have to fill out. It seems, you know, mundane perhaps, but my recommendation here is to title this to something that you can easily reference.

And my, pro tip is to use the invoice number here. dispute data doesn't give you a whole lot often, and it doesn't include the invoice once you dispute it. So just going to make it a whole lot easier for you to track and tie out if you use that. Dispute Summary. Just again, justify your case. Why are you disputing?

I would say find the sweet spot. kind of the Goldilocks approach. not too much, but not too little. Just write. You get the right information in there. It's going to help them to again, better research and validate your claim or your dispute. The last thing on here would be just additional attachments.

So, if you do have additional supporting evidence like an ASN or some type of images that would show how things are packaged, things like that, to help them better receive it, you do have an option to attach it here. I would say again, less is more. Try and find the sweet spot, but don't overload them with information.

They've only gotten a very short window of time to ultimately research your dispute or your case. So just keep that in mind whenever you're including information. These folks don't have a ton of time to research your case. So if you include too much information, they're often going to overlook it entirely.

Okay, so the last but not least here. This is where the the patience comes into play, but submit it, review it, or submit it and wait. so there's a couple of things that you can do in the meantime. one of these is, again, what we were talking about earlier, cancelling the invoice. so if you're doing additional research and you say, Oops, we, we actually, we goofed here.

We, we invoiced or over invoiced for this. still have an option to submit a credit memo, so there's no harm in that. Amazon's got a process on their side that's pretty rigid to where, they're likely not going to pay you out anything that's not due. If they do find inventory or the missing goods in the process of reviewing, your dispute, they'll pay you for it.

but if you do find evidence again, there's still options that you can do to issue credit or cancel a dispute if you feel like it's, truly been filed unjustly. and then again, waiting's a little bit of the hardest part sometimes, but, waiting patiently until you receive repayment once Amazon has reviewed and processed the dispute.

But, as far as the timing on that goes, just so everyone's aware, typically they say that it'll take about 7 to 10 business days to review a case. Sometimes we see that it takes a little bit longer, depending on how busy it seems like Amazon is, or their case volume is at the current moment in time.

But, typically again, it'll take Amazon 7 to 10 days to issue repayment once you've got something approved, and in general, about 30 days for them to action a case on average. So, just factor that into the timeline for repayment when you're waiting. ever so patiently on Amazon to both review the case as well as to repay.

But, that's what you should expect. The thing to remember is that Amazon doesn't allow for re disputes, at least not for shortages or price claims. It is kind of that one shot, one opportunity with them. So again, all the more reason why we're strongly encouraging you to validate claims. Take the time to do your due diligence and research before just going and disputing.

We do often see, again, the nature of Amazon's to receive process, that they're prone to error at the speed and the velocity that they operate. But again, doing your due diligence is going to help everyone at the end of the day. So again, we encourage that. So you get that one shot and that one opportunity, right?

let's talk about price claims now. So price claims, these ones are a little bit easier to understand as far as how they work. This really is a simple discrepancy in between an invoice and a purchase order as far as the item price. in the example here, again, it's pretty straightforward, but when we see that they're invoicing for a higher price.

Amazon is going to issue what they call a price claim or a PPV. So this is a purchase price variance, another one of these things that, again, Amazon loves their acronyms, but it's a price claim or a price discrepancy at the end of the day. This is a lot easier to fight from our perspective, when it's invalid, since it does involve, again, some pretty simple variables, since it's just a discrepancy in between the costs, the unit costs.

in between the PO and the invoice. So there's a couple of things that we see ultimately drive these. why might a price claim occur? Issues with missing POs. really that could just be something to do with the, confirmation step. Basically how items are coming in and some of that Initial setup.

Challenges that are tied to cost updates is another key one that we see. So, especially in the past couple of years with inflation and rising prices and costs in general and supply chain, we see that again, cost increases happen. Sometimes those updates are not only tough to get through, but tough to track and kind of update across the board in a variety of different systems.

Again, more scenarios of the left hand not talking to the right hand. So this is where issues like that will happen. A couple more things are just complications from rounding errors. So it sounds really silly, but if we're doing lots of math in between units, cases, palettes, tears, all of those fun things, then boils down to rounding errors when we're doing math and those types of different hierarchies of units and stuff at the end of the day.

So again, ensuring if you're doing rounding because you're doing a lot of translation in between cases and units or units and palettes and things like that, making sure the math ties out is pretty crucial because you can actually get Pricing claims from rounding errors. Switching products is another one of these two.

sometimes you've got a couple of different configurations or maybe different prices go into different folks, depending on what the specific channel is. So even if it's just switching the products in a form of data, nothing really that's physical happening. this can absolutely be something that causes price claims at the end of the day as well.

Okay. Now let's get to the avoiding piece. Again, these are a little bit more straightforward than some of the shortage claims, but implementing EDI for invoicing, again, just to ensure that there's a lot more consistency in the process from end to end, ensuring as far as the PO confirmation and things like that, that it's all consistent.

We're not confirming things at incorrect prices or costs, or that that cost is then consistent with how we're invoicing at the end of the life cycle as well. So again, consistency is key here for all of these attributes across all of the steps in the PO life cycle, which include the ASN and the purchase order.

But making sure that the currency is correct, the cost, the unit count, is all crucial again for ensuring that you're avoiding things like price claims. So setup accuracy in the catalog again is a key theme here, but this is where some of the switcheroos happened, where if you've got different UPCs or different, unit identifiers, having a mismatch here could also cause issues with how prices are getting attributed and therefore again, price claims.

So last thing on here is, maintaining pretty accurate historical records of any price changes that you've made over time. So if you do see issues arise, we can at least have some sort of historical record or time, drawn in the, drawn in the sand of time that says, Hey, this is when we made a change.

So we need to ensure that there's updates that happen across all our systems, or at least something we can point back to you that says if we see issues in the future, we know potentially why it happened.

So, pack quantities are another thing in here that are pretty important for us to ensure that are consistent, so that's another one of these things in between cases, units, etc. We want to make sure that all of the setup and configuration is done correctly. Invoicing steps here, again, pretty key. That's more just stuff with timing, but again, Things that could potentially cause price claim issues also could arise because of how invoices are getting submitted or with just, in general, how items are being received on that timeline with the amount of invoices that are also in the pipeline.

Okay, we're going to do the lightning round here with pricing claims here. So, there's no extra documentation that's needed to dispute these. Again, it's pretty straightforward as far as just needing to show that there's been a discrepancy in between that PO cost and that invoice cost. If you show that you've done it correctly in between that but Amazon's paid you at a lower cost, then you've got a valid case or a valid claim for going back and disputing that.

the ideal, dispute timeline with these is going to be within, 30 days of that invoice due date. So, getting these, getting on these as quickly as possible is, is ideal. there is a secondary layer with these as well. price claims, you can also go through a settlement process similar to your shortage claims.

So keep that in mind, something that you can do if you're, for whatever reason, you're not successful in getting any of those price claims resolved. You do have an additional settlement process that we can go through in order to manage those specifically.

So again, this is what we were talking about earlier with the shortage claims as well. Basically, you're going to get an email or notification that says, Hey, you've gotten a price claim. There's been some type of discrepancy now. in between, your invoices, and what you've initially agreed to on your PO.

We're going to follow a pretty similar dispute process as well, going through, reviewing and disputing price discrepancies. It's just going to be an additional action, or additional option that you can select on that invoices tab underneath the payments. From there, again, this will be selected as a specifically as a price claim deduction and underneath that Actions tab, you'll be able to dispute the price discrepancy, fall on a very similar workflow, clicking on Submit Dispute, take you through that portal where you're going to fill out basically this section here, it's an option two.

and Dispute Management. It's just another different route that will take you through. It's very similar, but you'll be able to input that specific invoice number, and then once you input that, it'll turn green, highlight the specific dispute that you actually want to dispute, and then click Continue. From here, it's a similar workflow to what you've seen with the other disputes, where you're going to fill out a dispute title.

Text for a justification and then click and continue. You'll be able to review, add any additional information, which will include justification, or additional attachments that you want to, prove your case to Amazon that they've underpaid on those. And just click Submit to Dispute.

[00:58:17] Allie: All right. Indeed, that was a lightning round. But thank you for getting through all of that content, Shawn. we don't have any submitted questions, but I, I did have a question. Absolutely. To the different ways that you showed to dispute a price claim. Are there advantages or disadvantages? Is it based off of the situation? Just some more context there.

[00:58:39] Shawn: It really is just user preference. I would say that there's no real distinct advantage or disadvantage. if you're going through option two, I think you have to be a little bit more, specific. You have to know exactly what you want to dispute so that you can input it into the form.

To move to the next step, going through that step one is more of the list view. So you can kind of go through and select as opposed to being more targeted. So user preference, I'd say, is what it boils down to at the end of the day. no real distinct advantage either way.

[00:59:15] Allie: Awesome. Well, thank you for that, Shawn. And thank you for walking through all of that content. I definitely walked away learning a couple new things about price claims and shortages. so we'll, we'll transition into, just our next slides. Wanted to call out that we are a little over time, so I want to be responsive. But wanted to say we have lots of additional resources.

You can see two of our Amazon eBooks and cheat sheets on here. So if you haven't checked those out, go download them. They're all free education for CPG suppliers. And then lastly, I know we said that we would do a product preview, but we are slightly over time, so I do want to be respectful of everyone, and just say if you are interested in reviewing how SupplyPike actually walks through and can automate a lot of this process, Shawn is your guy.

You should email him. You can also email me and I'll get you connected, to our team that works specifically with Amazon suppliers. But that is where you can go, or you can just fill out our Schedule a Demo form on SupplyPike. com. so we hope that you have a great rest of your Thursday, your baby Friday, and transition into the weekend.

Well, Shawn, anything to add before we sign off?

[01:00:33] Shawn: No, I'll just say that, I appreciate everyone, stay in tune, especially through the, the tail and lightning round. Sorry, we couldn't get to the product demo, but again, don't hesitate to reach out directly. I'd love to show you again in person, if you're truly interested in that.

and otherwise, like Allie said, enjoy the rest of your week and have a great weekend.

[01:00:53] Allie: Yes. Thank you all. Bye.

Hosts

- Read More

Shawn Oleson

Retail Insights Manager

Shawn is the Retail Insights Manager for Amazon at SupplyPike. His experience supporting 1P brands at Amazon helps our teams build a quality product for our customers.

- Read More

Allie Welsh-Truong

SupplierWiki Content Manager

Allie Welsh-Truong is an NWA native with a background in the CPG industry. As Content Manager, she develops and executes SupplierWiki's content strategy.

Presentation

Amazon Shortages and Price Claims

Download the Amazon Shortages and Price Claims slide deck for crucial info on avoiding and disputing shortage deductions and navigating price claims

Related Resources

Sponsored by SupplyPike

About SupplyPike

Grow your retail business without frustration. Fight deductions, meet OTIF goals, and maximize cash flow in the built-for-you platform, powered by machine learning.

About

SupplyPike helps you fight deductions, increase in-stocks, and meet OTIF goals in the built-for-you platform, powered by machine learning.